ESI reinforces its Welding Simulation Suite with Visual-WELD

Visual-WELD is a workflow-based software user interface for modeling welding fabrication processes including all manufacturing details. It reinforces ESI’s Welding Simulation Suite by facilitating fast and accurate distortion and weld quality virtual engineering at any stage of product design and manufacturing. Simplicity is indeed the key of this new interface.

Dedicated to all engineers who manage the design and fabrication of welded assemblies, Visual-WELD helps reach a stress minimized welding assembly within tolerances at minimal cost, respect customers’ specifications and secure the production. Knowing that the failure of even the simplest weld can cause the failure of the entire design, Visual-WELD helps control component weld quality in terms of temperature, micro-structure and residual stresses. Consequently, it enables engineers to avoid problems such as backside temperature, stress corrosion cracking as well as crack initiation due to tensile stresses at the wrong place. Engineers are also able to produce uniform stress distribution and uncover hot stress spots all over the design due to the welding fabrication process that would have negative impact on the fatigue life.

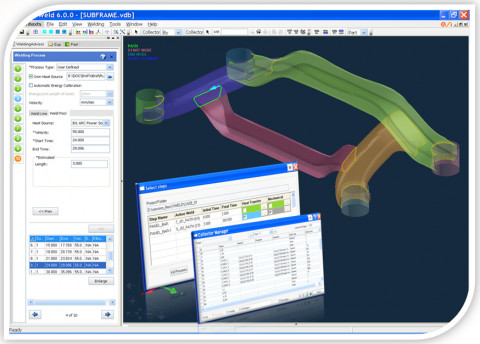

ESI’s Welding Simulation Suite, with the complement of Visual-WELD dedicated user interface, offers the full set of welding engineering methodologies needed by designers, process planners and manufacturing practitioners. Visual-WELD is the latest simulation tool developed within ESI’s Visual-Environment, integrated and collaborative software environment, encompassing the complete workflow for realistic, physics-based Virtual Prototyping. Coupled with Visual-Mesh and Visual-Viewer, pre- and post-processing modules of Visual-Environment, Visual-WELD addresses the Welding Engineer’s activities using a single data model, from interfacing to CAD formats, CAD cleanup, meshing, model set-up and post-processing.

Indeed, the latest release of ESI’s Visual-Environment version 6.0 now includes all multi-physics involved in Welding Simulation. ESI offers today a fully industrialized collaborative software environment, including the following major components:

Visual-Mesh, complete meshing tool which supports CAD import, 2D and 3D meshing and editing for linear and parabolic meshes;

- Visual-WELD, dedicated workflow-based welding simulation interface that enables Single-Pass and Multi-Pass Welding simulations. The complete workflow is represented with sequential and intuitive steps. The set up requires the minimum amount of input and allows engineers to be fully operational within a few hours.

- Visual-Viewer, post-processing tool with advanced plotting utilities. It allows the display, synchronization and animation of several computed physical quantities at the same time, and the comparison of result variants. It is thus easy and straightforward to identify and understand problems and thus take the necessary actions to improve the welded design or its fabrication.

“Visual-WELD was designed with the objective of allowing our customers to benefit easily from more than 100 men-years of experience in welding simulation”, said Dr. Frederic Boitout, Welding Project Manager, ESI Group.

“Included in the latest version of Visual-Environment, Visual-Weld delivers a great combination of intuitive interface and simulation of the physics of materials in this domain. Our customers are already excited about the possibilities this new Welding Simulation Suite brings to improve their welded products and welding processes”, added Dr. Yannick Vincent, Welding Product Manager, ESI Group.

Visual-Environment version 6.0 release also includes general performance enhancements and notable updates of existing applications, all aiming at contributing to an increase in productivity and efficiency. Indeed, animation speed and display operations are today two times faster than the previous versions and memory usage has been optimized by 25%. The increase in animation speed enables faster multi-physics animations and results comparison.

For more information, please visit: http://www.esi-group.com/products/welding and http://www.esi-group.com/products/visual-environment