ESI helps car manufacturers improve biofidelity for vehicle safety

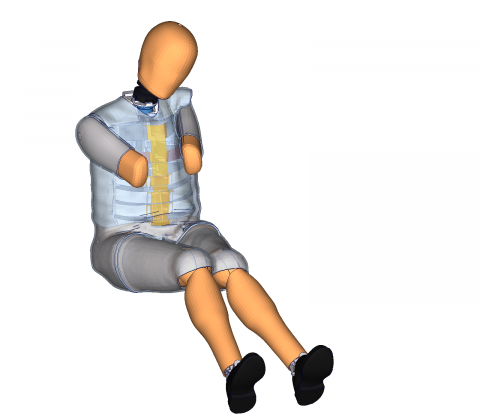

Based on the positive experience of high-quality dummy model developments within the German Association for Research on Automobile Technology (FAT), five German car manufacturers representing the Partnerships for Dummy Technology and Biomechanics (PDB) and software vendors including ESI, worked together to develop a high-quality WorldSID 50th Finite Element (FE) model − a new advanced worldwide accepted dummy of improved biofidelity to assess the injury risk to vehicle occupants in side impacts.

As global markets require international rules and standards, harmonized safety regulations are essential. The PDB, which was founded in 2002 as a cooperative venture between Audi, Mercedes, Porsche, BMW and Volkswagen in the field of crash test dummy technology, biomechanics and simulation, participates in national and international committees to support worldwide efforts towards harmonization. The main objective of the WorldSID 50th FE model, representing an average sized adult, is to replace the EuroSID-2 and US DOT SID simulation models.

The requirement of a validated and high-quality FE model, such as the WorldSID 50th, also stems from the constant need for vehicle manufacturers to reduce costs and save time. Indeed, dummy models are key for vehicle manufacturers as they are the measuring tool of a car’s overall quality. Physical dummies are expensive and it typically requires 6 to 7 hours to perform a single crash test. In contrast the virtual counterpart of a dummy model allows for the completion of dozens of virtual crash tests per day.

The WorldSID 50th FE model is based on the latest version of the physical dummy whose FE mesh was developed using the CAD Data of ISO 15830 of 2005. The development of the WorldSID 50th FE model is primarily based on customer requirements, as communicated through the PDB. Validation tests covered a wide range of expected load conditions in vehicle environments, and the validation process went far beyond the certification or component tests. The complete dummy was validated against different barrier-sled tests which illustrated the behavior inside the car cell. By checking and improving test equipment and the corresponding virtual models, the PDB helps manufacturers reliably fulfill their high-quality standards in the field of vehicle safety.

"During the project, the collaboration between Audi and ESI was excellent,” said Björn Hohage, Occupant Simulation, Side Impact, AUDI AG. “I had the opportunity to test, early in the development process, the latest enhancements of the new WorldSID 50th FE model developed by ESI engineers, and to provide them with feedback to improve it. This new dummy model is now ready to be used at an industrial level.”

ESI first contributed to the improvement of the simulation model to allow the release of the first official industrial version of the WorldSID 50th FE model. While the first R&D version (V1.5) already provided good results in all investigated load cases from more than 200 tests, the current industrial version (V2.0) benefits from a number of enhancements, including new features of ESI’s solution for crash and safety simulation (Virtual Performance Solution version 2010), fine tuning of the neoprene suit of the dummy, new material properties for the lower leg area and shoes, as well as extended friction parameters for knee and ankle joints. A detailed user manual also presents the correlation between simulation and experimental results.

ESI is an official reseller of the WorldSID 50th FE model and further work in dummy development is in progress.

“We are particularly proud of our WorldSID 50th FE model. The model already correlates very well with the complete set of component, calibration and barrier tests. This is the result of systematic and accurate work where every detail was modeled in-depth,” said Dr. Charles Thibaud, Technical Director at ESI GmbH. “During the FE model development, the stability, accuracy and speediness of Virtual Performance Solution have positively supported our efforts.”

ESI also offers a wide library of validated dummy models, covering all safety standards. For frontal impact, the Hybrid III FE and Multi Body models – and the THOR FE model are available. For side impact the EUROSID2, the US DOT SID and the SID-IIs are also available. For rear impact, the BioRID II is available. As well as dummies, ESI’s model library also includes barriers and biomechanical human models.

For more information, please visit: www.esi-group.com/products/biomechanics