Discover the latest version of ESI’s system modeling solution, SimulationX 3.8

Paris, France – November 21, 2016 – ESI Group, leading innovator in Virtual Prototyping software and services for manufacturing industries, announces the latest version of SimulationX, one of the best known software brands in the field of systems modeling. Strengthening ESI’s portfolio, since the acquisition of German company ITI GmbH at the beginning of this year, SimulationX is an industry-proven software platform for dynamic multiphysics system simulation, customizable to the specific needs of diverse industries. The latest version of SimulationX (3.8) delivers significant enhancements and additional features for the simulation of drive systems, electromechanics, hydraulics, mechanics and pneumatics in various industries including transportation, energy, industrial and mobile machinery, as well as mining. Furthermore, completely new functionalities facilitate applications in the development of tomorrow’s biomedical sector and smart, green cities.

Supporting the open-source modeling language Modelica®, ESI’s SimulationX stands out through its flexible, easy-to-use and open architecture. The comprehensive nature of its integrated libraries of realistic physical models has helped establish SimulationX as the indisputable reference in a variety of industrial fields where the intersection of physics disciplines (including mechanics, electronics, controls) is increasingly advanced (e.g. electric or hybrid powertrain applications). Today, SimulationX is used by over 700 customers from every industrial sector in 27 countries.

IAV, one of the world's leading automotive engineering service providers, uses system simulation to optimize powertrain and vehicle performance.

We achieve continuous optimization of our internal development processes and timeframes by effectively using SimulationX. We are looking forward to the variety of new features and enhancements in the new version 3.8.

says Dr. Bernd Findeisen, Manager CAE/Test at IAV GmbH.

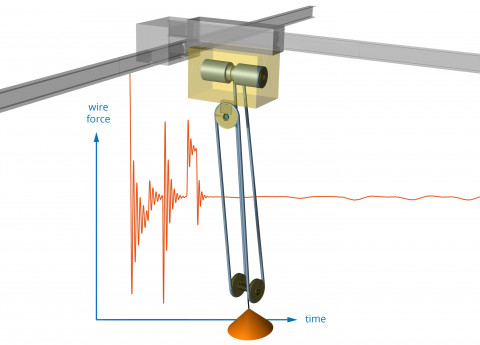

Among the important enhancements brought by SimulationX 3.8, users from various industries, particularly those addressing mobile and industrial machinery as well as subsea and oil & gas applications, benefit for instance from detailed and convenient simulation of complex three dimensional rope and belt drives. The new, dedicated model library with pulleys, drums and belts/ropes enables the fast and efficient set-up of detailed models to evaluate all interactions between belt or rope, input, output and controls and to determine forces and torques. Also mechanical engineers in the energy, machinery and automotive sector now benefit from readily available dedicated circuit model elements, to integrate them in models of their machinery. Consequently they can achieve efficient simulation and detailed analysis without the need for detailed knowledge of electrical and controls engineering. Broader functionalities have been added, for example to model and simulate detents, closing devices, disk cam mechanisms, indexers as well as dog clutches in manual transmissions in an easy and comfortable way. Finally, the new model library “Hydraulic Brake Systems” assists engineers in the automotive industry to ensure both safety and comfort during braking maneuvers for cars and motorbikes (including influences of ABS and ESP); ultimately speeding up the development processes of brake systems.

The new SimulationX 3.8 “Microfluidics” library provides comprehensive model elements to efficiently model, simulate and analyze the physiological flow behavior through various organs in an artificial microcirculatory system. Researchers and engineers in the healthcare sector can now simulate the fluid system in a more efficient way, accelerating the development of diagnostic equipment such as microfluidic cell culture and lab-on-a-chip systems. System modeling enables the pharmaceutical and cosmetic industries to reduce animal testing, while cutting down development cost and times. Thanks to the state-of-the-art “Non-Newtonian Fluids” library, engineers and scientists can also obtain reliable information about the behavior of complex fluid systems with the objective to expand the simulation of technical systems to precise, virtual evaluations of non-newton fluids such as polymer melts, lotions and drilling mud.

In addition, SimulationX 3.8 addresses the challenges faced by the urban planners, civil engineers and energy professionals who are working together to develop smart, green cities of the future. Thanks to ESI’s software, they are now able to simulate and optimize the efficiency of energy systems for modern cities, including heat and combined grids. Using the dedicated SimulationX model library “GreenCity” allows them to easily model and simulate complex energy systems including volatile energy sources, energy storage and consumption, as well as charging infrastructure for electric vehicles.

Beneficial for all users across all industry sectors, SimulationX 3.8 features a more intuitive graphical user interface as well as improvements on the calculation method and result visualization, to speed up all important work steps – modeling, calculation and analysis – up to ten times.

For more information about SimulationX, please visit www.simulationx.com/

(SimulationX is a registered trademark of ESI ITI GmbH. Modelica® is a registered trademark of the Modelica Association.)

For more ESI news, visit: www.esi-group.com/company/news

SimulationX – Media Relations

Denise Börner

+49 (351) 26050 169

ESI Group – Media Relations

Céline Gallerne

+33 1 41 73 58 46