ESI Releases PAM-RTM 2010

Infusion is a process widely used to manufacture large components such as wind blades or wing boxes. However, determining vent locations and injection strategy is a real challenge for large, complex parts made of different composite materials and inserts and for which the resin flow through the thickness is not uniform. Until now, no simulation tool could accurately manage these large or complex components requiring volumic modeling, costing companies multiple expensive and time- consuming trials to reach a working manufacturing process.

PAM-RTM 2010 is part of ESI’s Composites Simulation Suite of dedicated industrial software for the design, performance and manufacturing simulation of composite components. The 2010 release of PAM-RTM includes a high performance solver enabling Distributed Memory Processing (DMP) computations for Liquid Composites Molding (LCM) process simulation. It covers a wide range of manufacturing processes based on LCM, helping process engineers and designers to quickly and efficiently evaluate manufacturing strategies and optimize process parameters regardless of component size.

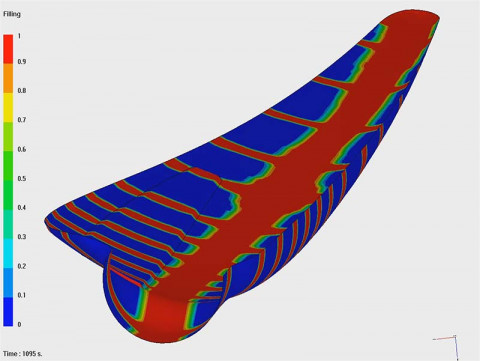

Thanks to the DMP solver capability and an optimized graphical interface, components using millions of elements (shells as well as solids) are now treated and, more importantly, simulations can be completed in a matter of hours. PAM-RTM 2010 addresses industrial time constrains with the highest level of accuracy, enabling LCM simulation for very large parts, for complex geometries requiring a detailed mesh and for thick parts in which the non-uniformity of the resin flow through the thickness cannot be neglected. PAM-RTM 2010 is a unique and powerful tool dedicated to industries – including the wind energy and aeronautic sectors – that manufacture complex or high-dimensioned Liquid Composites Molded components.

“Snecma Propulsion Solid (Safran Group) designs, develops and produces solid rocket motors and composite materials for defense, space, aeronautics, and industry applications. Recently, we showed at an RTM conference organized by the PPE (Pôle de Plasturgie de l’Est) some of our achievements in the development of flex-seal cowls,” said Martine Dauchier, R&D Phenolic Ablative Materials Engineer, Snecma Propulsion Solide, SAFRAN Group. “Introducing 3D RTM composite materials for flex-seal cowls led to materials and assembly cost savings. Together with the PPE, using PAM-RTM simulations, we successfully designed optimized RTM processes accounting for the specific reinforcements injected. These flex-seal cowls are now in use on the nozzle of the VEGA P80 Motor.”

PAM-RTM 2010 offers additional enhancements and consolidations of 2009 functionalities such as the automatic injection flow rate control to reduce porosity in the parts and the “one shot” simulation to rapidly estimate the last area to be filled and filling time, the conditional opening and closing of the gates, the influence on permeability of fiber shearing during draping – modules originally developed by the ‘Chaire sur les Composites à Haute Performance (CCHP) of École Polytechnique de Montréal’ – and the advanced draping functionalities for more realistic fiber orientation prediction, among other improvements. All these enhancements provide users with a more rapid decision-making solution for process, part quality and mold optimization.

Among the new functionalities of 2010, two major developments also from the Ecole Polytechnique de Montréal have been implemented:

- automatic determination of the best location of injection ports (based on genetic algorithms);

- Compression Resin Transfer Molding (CRTM) and Articulated Compression Resin Transfer Molding (A-CRTM) process simulation.

“PAM-RTM 2010 release represents a major contribution to ESI’s Composites Simulation Suite with its high performance solver moving back the main limitations of Liquid Composite Molding simulation,” declared Mathilde Chabin, Composites Product Marketing and Business Development, ESI Group. “This version was motivated by a growing need in wind energy and aeronautic industries where the complexity and size of composite structures keep increasing while the highest part quality in less time is required.”

For more information, please visit: www.esi-group.com/products/composites-plastics/pam-rtm