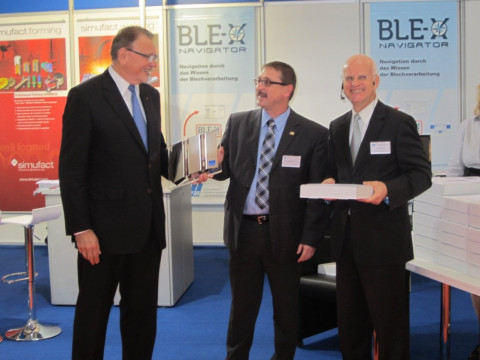

ESI honored with the "Innovative Alliance" EFB award at EuroBLECH 2012

ESI Group, pioneer and world-leading solution provider in Virtual Prototyping for manufacturing industries, received the EFB’s “Innovative Alliance” prize at EuroBLECH 2012, an important international event dedicated to Sheet Metal Forming, which took place from 23 to 27 October in Hanover, Germany.

This award recognizes the contribution of members of the European Research Association for Sheet Metal Forming (Europäischen Forschungs-gesellschaft für Blechverarbeitung, or EFB) who successfully engage in industrial networking with other companies and industrial institutions operating in the field of Sheet Metal Forming, while promoting research towards new materials, processes and quality control.

Andreas Renner, GM of ESI GmbH, declares, “We are very proud of this award, which speaks to our continuous commitment to help the industry be more competitive by developing breakthrough simulation technologies. We believe this prize also recognizes the contribution of our customers and partners. Only through our continuous dialogue can we develop practical solutions to address the most relevant industrial challenges of our time.”

Under the motto “Experience your Product”, ESI presented the latest version of its Sheet Metal Forming software simulation suite PAM-STAMP 2G and PAM-DIEMAKER for CATIA V5, addressing design and manufacturing issues directly within CATIA V5’s generative modeling environment.

The ever-increasing need for higher quality sheet metal products, and the need to optimize processes to cut manufacturing costs, calls for innovative simulation solutions. With PAM-STAMP 2G and PAM-DIEMAKER for CATIA V5 , ESI provides OEMs with established solutions that have long been recognized by the Sheet Metal Forming industry for simulating and optimizing products or parts, and consequently help them achieve the panel shapes required to deliver exciting designs and structural performance that exceeds safety, weight reduction and other objectives.

Visitors also experienced ESI’s new range of collaborative decision-making solutions: IC.IDO. Using immersive 3D technology, visitors could visualize virtual prototypes and experience the value of embedded real time physics for collision detection and simulation of flexible pipes and cables. With IC.IDO , companies bring their industrial products to life, long before any physical prototype exists. This allows them to collaboratively make decisions cross-function, cross-area and cross-discipline for every important phase of the development process.

Andreas Renner adds: “EuroBLECH is an excellent opportunity for ESI to establish a dialogue with industry specialists and of course, our customers. The solutions we presented at EuroBLECH triggered vivid interest.”